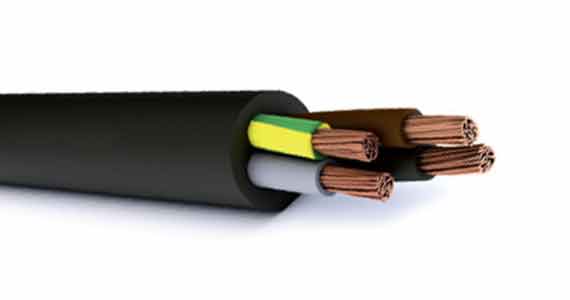

Rubber Cables

We are counted amid the well-known Rubber Cables Manufacturer & Supplier in India. In keeping with the company's commitment to technological advancement, elastomer materials such as Polychloroprene (PCP), Chloro-Sulphoneted Polyethelene (CSP), Nitrile Rubber /PVC blends, Ethylene Propelene Rubber (EPR), Ethylene Vinyle Acetate (EVA) and Silicone have been specially compounded to meet numerous heat oil and fire resisting requirements. In the recent years, Relemac Technologies has also developed special Rubber Cables & Elastomeric Fire Survival Cables for power, control and instrumentation wiring. All our Elastomeric Rubber Cables available in standardized as well as customized specifications. Additionally, the Elastomeric Cables are reasonably priced too. .

Elastomeric compounds for insulating and sheathing of cables are formulated to meet the requirement of IS 6380, BS 6899, IEC 60502 and other international specification.

Note :

- • The number of wires is approximate and wire diameter is nominal; they shall be such as to satisfy the requirements of conductor resistance as per Class 5 of IEC 60228 / DIN VDE 0295 / IS 8130 / BS 6360.

- • 4 core and 5 core flat cables are available on request.

| GENERAL CONSTRUCTION (Conforming to IS 9968 Part 1) | |

| Conductor | Annealed tinned Copper wires Solid (Class 1), Stranded (Class 2), flexible (Class 5) complying with the requirement of IS 8130-1984 |

| Seperator Tape | Suitable material seperator tape may be applied over the conductor |

| Insulation | General service elastomer compound Type IE1 of IS 6380-1984 Heat Resisting elastomer compound Type IE2 of IS 6380-1984 Silicone Rubber Type IE 5 of IS 6380-1984 |

| Core Identification | Coloured insulation, Nos.PE tape, Coloured proofed tape, Nos. printing |

| Fillers | Natural or synthetic fibres or elastomer suitable for the operating temperature and compatible with the insulating material |

| Sheath | General service sheath Type SE1/SE2 of IS 6380-1984 Heavy Duty Sheath Type SE3/SE4 of IS 6380-1984 |

| Working Temperature of Commonly used Elastomeric Insulating and Sheathing Materials | |

| Material | Max.Cond.Temp. for Continuous opertinuous operation Deg C. | Max. Cond. Temp. For short circuit Deg C. | Min. Working Temp. Deg C. |

| Natural Rubber(VIR & TRS) | 60 | 200 | -55 |

| Ethylene Propylene Rubber (EPR) | 90 | 250 | -50 |

| Polychloroprence (PCP) | 70 | 200 | -40 |

| Chlorosupphonated Polyethylene (CSP) | 90 | 200 | -35 |

| Silicone Rubber | 150/180 | 350 | -55 |

| Hr Natural Rubber (HR VIR) | 75 | 200 | -55 |

| Styrene Butadience Rubber | 60 | 200 | -55 |

| Butyl Rubber | 85 | 220 | -50 |

Silicon rubber insulated cables

are used in electric utilities such as the generation and transmission of electricity. Long service life under normal environment in Nuclear and conventionally powered generating stations plus safety considerations are the significant factors of these electric appliances. When exposed to fire, Silicon offers circuit integrity, low smoke evolution, and freedom from halogen acids.(For e.g. High Furnaces Generator, Electrical Furnaces, Cokd Ovens, Driers, Bakeries & Blast Furnaces).

Applications:

Steel Mills, EOT Cranes, Airport Lighting, Ships, Nuclear & Thermal Power Stations, Wind Power Mills, Electrical Machines, Textile Machines, Construction Equipments, Turbines.

Welding Cables

RELEMAC Welding Cables Double Insulated, Extra Flexible, Orange and Black Jacket

FEATURES:

- • Based on CENELEC HD 22-6 31, VDE 0282 ,IEC 245-6, IS 473, BS 638-4.

- • Outstanding toughness & durability.

- • High resistance to cuts , tears & abrasion.

- • Resistance to oil , solvents and chemicals.

- • Excellent ozone and weather resistant.

APPLICATIONS:

Welding: Designed for the secondary (high current) connection with automatic or hand - held metal arc welding electrodes. It is suitable for flexible use under rugged conditions, on assembly lines and converyor systems, in machine tool and automatically operated line and spot welding machines.

Power:

Earthing/return leads, power feeds to electrolytic plating process, Busbar connection, transformers, generators, aircraft servicing equipments etc.

CONSTRUCTION:

Conductor: High conductivity, bare annealed copper flexible conductor.

Sheath: Double sheathed with specially developed thermoplastic Elastomer (TPR/TPE), outer layer is orange coloured.

CURRENT RATING:

The maximum current ratings of flexible welding cables for different duly cycles are based on an ambient air temperature of 25 C and a maximum conductor temperature of 90 C. The percentage duly cycles for various processes and applications are as follows:

| 1 | Automobile Welding | up to 100% |

| 2 | Semi-automatic welding | 30% to 85% |

| 3 | Manual Welding | 0% to 60% |

| 4 | Very intermittent or Occasional Welding | up to 20% |

VOLTAGE DROP:

When total cable lengths in excess of 15 meters, are involved , it may be necessary to use cables of larger cross section to ensure that the voltage drop is not excessive and welding currents are maintained at adequate levels.

| Cross - Sectional area |

Max. Conductorb resistance at 200C | Nominal Thickness of sheath | Min. Overall diameter | Max. Overall diameter | Current Ratings | |||||

| Welding Application |

Non Welding Application | |||||||||

| Duty Cycle | ||||||||||

| 100% | 85% | 60% | 30% | 20% | ||||||

| mm2 | ohm/km | mm | mm | mm | amp | amp | amp | amp | amp | amp |

| 10 | 1.91 | 2.0 | 7.8 | 10.0 | 105 | 115 | 135 | 190 | 235 | 110 |

| 16 | 1.21 | 2.0 | 9.0 | 11.5 | 135 | 145 | 175 | 245 | 302 | 138 |

| 25 | 0.78 | 2.0 | 10.0 | 13.0 | 180 | 195 | 230 | 330 | 402 | 187 |

| 35 | 0.554 | 2.0 | 11.5 | 14.5 | 225 | 245 | 290 | 410 | 503 | 233 |

| 50 | 0.386 | 2.2 | 13.0 | 17.0 | 285 | 310 | 370 | 520 | 637 | 295 |

| 70 | 0.272 | 2.4 | 15.0 | 19.0 | 355 | 385 | 460 | 650 | 794 | 372 |

| 95 | 0.206 | 2.6 | 17.5 | 21.5 | 430 | 470 | 560 | 790 | 961 | 449 |

| 120 | 0.161 | 2.8 | 19.5 | 24.0 | 500 | 540 | 650 | 910 | 1118 | 523 |

| 150 | 0.129 | 3.0 | 21.5 | 26.0 | 580 | 620 | 740 | 1040 | 1297 | 608 |

| 185 | 0.106 | 3.2 | 23.0 | 29.0 | 660 | 715 | 850 | 1200 | 1476 | 690 |

| 240 | 0.0801 | 3.4 | 27.0 | 32.0 | 710 | 770 | 916 | 1296 | 1587 | 744 |

| 300 | 0.0641 | 3.6 | 30.0 | 35.0 | 800 | 850 | 1035 | 1450 | 1790 | 840 |

| 400 | 0.0486 | 3.8 | 33.0 | 39.0 | 925 | 1000 | 1195 | 1690 | 2070 | 970 |

| Rating factors for variation in ambient temprature | ||||||||||

| Ambient temperature°C | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 |

| Rating Factor | 1.04 | 1.00 | 0.96 | 0.91 | 0.87 | 0.82 | 0.76 | 0.69 | 0.64 | 0.57 |